|

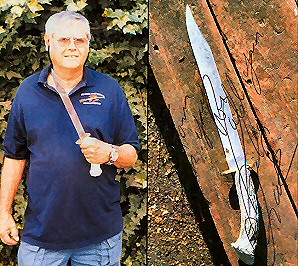

Knifemaker Chuck Stapel

of Los Angeles has been

making knives for three decades, so far. He is the

second of four generations of knifemakers, counting

his father, his son and his grandson. Charles Stapel,

Sr., made his first knives as far back as World War

11. Chuck's son, Craig, made his first knife about

1981 and Craig's son follows his grandfather around

the shop every chance he gets. He has begun his own

knifemaking career, too.

Chuck Stapel continues making knives, swords, eating

utensils, corkscrews and art sculptures on a

full-time basis. For the past 20 or more years, he

has found a market for his works in the nearby

motion picture and television industry.

|

|

Look at the handle detail of the Bowie used in "The Alamo." Three models of the knife were made; only one had a sharpened blade edge. The handle is cast plaster to resemble natural stag and so all three movie knives would look alike.

|

"I made my first movie knife in 1983 for a

picture called, `No Mercy,"' Stapel said.

"I was contacted by a local prop master I knew.

He was involved with the movie and asked me to come

up with a pattern. We came to an agreement, I made

the knife and it was used in the picture."

That first movie knife started things rolling for

Stapel. The knifemaker spent much of his earlier

working years as a carpenter and locksmith in

Southern California. He became acquainted with many

of the prop masters and prop houses for the

entertainment industry. He dropped off his business

card whenever he passed one of the houses. Over the

past 20 years, Stapel has made knives for 40 or 50

productions; he says he really has not kept count.

His most recent contributions are for the recent

movies, "The Alamo," "Once Upon A

Time in Mexico" and "Kill Bill."

Not every knife he has made has had what might be

termed a leading part, but the Bowie knife appearing

in "The Alamo" may be seen frequently and

prominently in the film story.

|

Longtime custom Knifemaker Chuck Stapel holds his latest movie knife, a Bowie pattern for "The Alamo." (Right) This is Chuck Stapel's version of a Bowie knife used in "The Alamo." The blade was made to look slightly rusty and well used. It is 12 inches long and measures 18 1/2 inches long

overall.

|

|

Stapel had to construct several Bowies, all to look

alike. The 12-inch blade is made of 01 tool steel

and the handle measures about 4 I/2 inches long. The

handle is cast from an original stag design of

molded plastic, thus each model looks the same as

the others. The guard is brass. A leather sheath was

also required for filming. Stapel was asked to

"age" the blade to look well used and

appear not in brand new condition. So, up close, the

blade looks stained and dented as if it had been

heavily used before the motion picture story takes

place. For the filming, Stapel was asked to produce

one sharpened blade and two unsharpened knives.

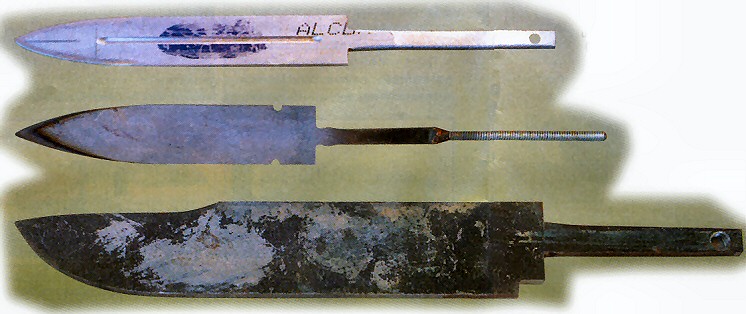

Another popular movie of recent years, still shown

on the cable networks, is "City Slickers."

Chuck Stapel made the big Bowie-pattern knife

handled by actor Jack Palance. That one had an 8

1/2-inch

blade, but was visible for only a few seconds in the

film.

Other movies or television stories

with knives by Chuck Stapel include the TV series,

"Magnificent Seven" and

"Deadwood," plus movies such as

"Tombstone" and "9mm." For

"9mm" the 5 3/4-inch blade pattern was

made only of aluminum, measuring 10 inches long

overall. For "Magnificent Seven," Stapel

provided three new steel patterns. For

"Tombstone's" Doc Holliday character, the

knife chosen was a dagger pattern.

|

(Top) Knifemaker Chuck Stapel reports that several movies have used this aluminum dagger pattern. (Middle) This dagger pattern blade was for the movie "Tombstone." (Bottom) This blade pattern was contracted by Chuck Stapel and used in the movie "City Slickers" by Jack Palance's character. |

One design Stapel has been making for years is his

idea of a boot knife, which has a 3-inch blade of

AFB-L stainless steel and an ivory Micarta handle.

The handsome knife is 6 3/4 inches long overall. Any

particular scene may end up on the cutting room

floor, but Stapel thinks his boot knife may appear

in a "Deadwood" television episode.

|

This boot knife is a Stapel standard design, popular with many customers. It also appears in the TV series "Deadwood." It features a 3-inch

AEB-L stainless steel blade and an ivory Micarta handle. Custom versions may have scrimshaw on the handle. |

"As a result of my long association with the industry, I have developed an excellent

reputation with the prop houses," Stapel said.

"Now many of them come to me first when they

are looking for some sort of movie knife. I'm

prepared to produce just about anything the prop

masters may need, except retractable-blade and

rubber knives. I don't make those."

Stapel does not reveal the amount he is paid for

making movie knives, but admits his time and efforts

are rewarded. However, he has never received what is

known

as screen credit for any of his work. "I have

and still enjoy the filming process," he says.

"Sometimes, I am invited onto the sets where

the action using my knives takes place. I remember

one scene that required six hours to film. But when

the television episode was shown, the knife scene

lasted only about 15 seconds. Sometimes, you have to

look fast to see the results of my work.

"I am pleased that the

industry people believe in me and this aspect of my

knifemaking. Over the years, it has been a lot of

fun and I always enjoy talking about ,movie

knives."'

Stapel admits that, with so many of his knives in so

many stories over the past 20 years, he has lost

track of which ones went where and who used them for

the stories. From time to time he sees one of his

old knives being used for a second or third story.

As he says, the job is to produce what the prop

master wants. Once the product is delivered, the

creator has little influence as to what happens to

it.

Throughout his three decades of custom knifemaking,

Chuck Stapel has been one to experiment with new

designs and

materials. He makes blades of 0-1, D2 and 440C, but

has become one of the first to recognize the

properties of AEB-L stainless steel. He likes

working with the steel and finds that it holds an

edge well.

Lately, he has found a market for individual knife,

fork and spoon sets, as well as for another kind of

eating set consisting of a 3-inch stainless steel

tanto blade with a bone handle. Custom chopsticks

are included with a choice of a custom sheath or a

box for the set.

Another new direction for the maker is the use of

Damascus steel. Stapel has been using forged

Damascus from fellow Californian Jim Ferguson. The

knife features a striking 3 1/2-inch blade with a

3 3/4-inch fossil walrus ivory handle, Micarta

spacer and a leather thong loop. A leather sheath is

optional.

|

This is not a movie knife. Stapel is using twisted nickel Damascus blades from Jim Ferguson with a 3 1/4-inch blade. The knife is 7 1/4 inches long overall with a fossil walrus ivory handle, a Micarta spacer and a leather thong loop at the butt.

` |

|

Stapel is one of the fastest

custom knifemakers around when it comes to one of

his standard designs. A small skinner with a Micarta

handle can be turned out in a couple of hours. He

starts with a piece of heat-treated steel, then

shapes, grinds, drills, clamps, cements and sharpens

the small knife while you watch. The slowest step is

waiting for the two-part epoxy to harden. If the

knife is a simple "economy" model, he will

use a shrink-wrap handle cover over the full tang

knife and shave off half the time. The current

design features a 3 3/4-inch blade of high carbon

steel with black shrink wrap on the handle for an

8-inch knife overall. A custom leather sheath is

optional.

Chuck Stapel retired from his regular job with several Los Angeles school

districts a couple of years ago and concentrates on

knifemaking and competitive shotgun shooting. Plus,

the knifemaking has also led to several movie bit

parts for Stapel, mostly in Westerns and other

costume period stories. He states that his

appearances have been almost too brief for even him

to spot when the movie or TV show airs. `

The Los Angeles resident now

spends a considerable amount of time attending and

supporting various celebrity fundraising shooting

events around the country. He regularly travels to

celebrity shoots from Florida to Hawaii, about 14

such events a year. He competes as a shooter in many

of the events, often taking the top shooting honors

in his category. He also donates his knives as

awards or as prizes to be auctioned to raise funds.

At one event, one of Stapel's knives brought $12,000

for a charity.

Stapel remembers, "I have met

and shot with many celebrities such as Robert Stack,

Tom Selleck, Chuck Norris, the Mandrell Sisters and

many other artists, especially country singers,

musicians, artists and actors. We have raised money

for such groups as Children's Diabetes, `Wish Upon A

Star,' the Paralyzed Veterans of America and other

groups.

|

"I feel fortunate to have helped the less

fortunate and to be able to participate in

these shooting events as well. It is a win-win

situation. I can help others while doing what

I enjoy doing-making knives and

shooting."

|

Stapel's latest Eating Set is his "Buffalo

Bonsai " featuring a 3 3/4 inch High carbon

blade with a satin finish. The

knife also has a half-hard Brass Guard and spacer.

The

Handle is made of Asian cherry wood with inclusions, left in natural beauty

with fossilized walrus tusk end butt.

The Chopsticks are comprised of

hand-made Lacquered Wood.

Please

Click Here for Ordering Information

|

|

Chuck Stapel is not, of

course, the only maker to produce knives or

swords for the entertainment industry. There

are many others. As long as Westerns,

adventure stories, pirate movies, science

fiction and gangster films are made, somebody

must satisfy the actors, writers, producers

and prop masters. Look closely-astute viewers

may see a familiar knife.

*****

|

|